Why Rebuild Your Turbocharger?

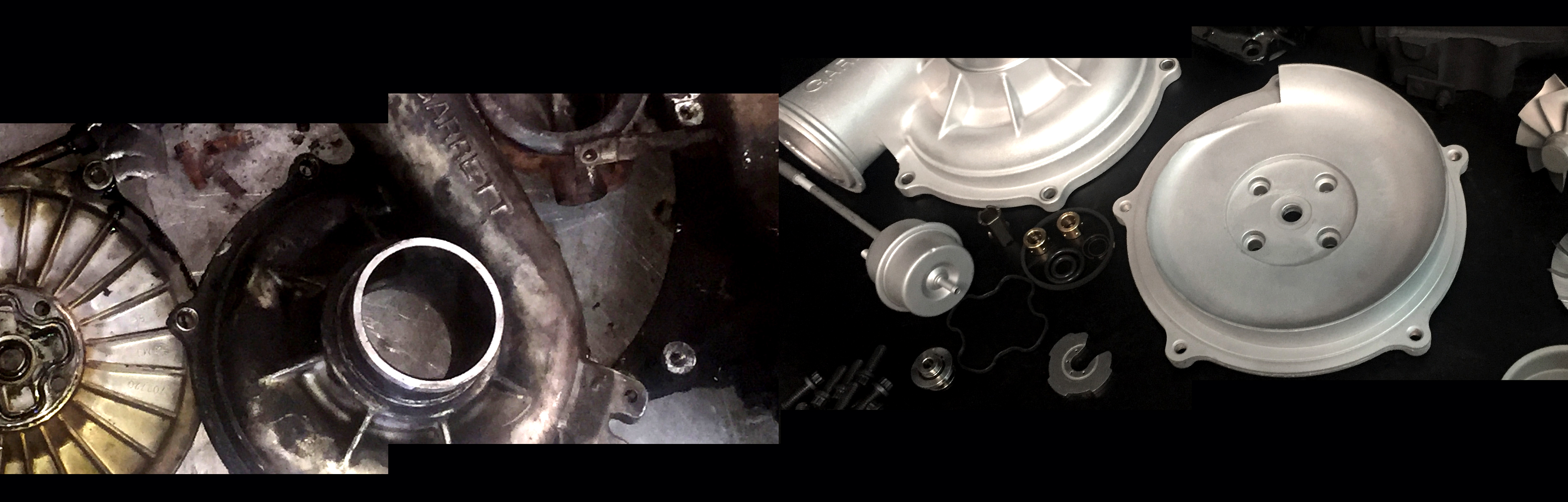

We get this very question asked to us on a regular basis, why should I have my turbocharger rebuilt specifically? The answer is really quite simple, your turbocharger failed for a reason and it is very important to know why. When we dissasemble your turbocharger it tells us a story; the condition, appearance, and wear factors of the individual internal components give the details about what went wrong and why the turbo failed. While taking the time to carefully dissasemble and inspect your turbocharger we will learn alot about the condition of your car, your maintenance and driving habits as well as a few other technical things; like how good your engine oil really is. Once we know this information, it will be very easy for us to help you make all the right decisions for your newly rebuilt turbocharger to live a healthy life.

Now, in general it is really great to rebuild your turbocharger just for the money savings when compared to purchasing a new turbocharger. The average cost of a turbocharger rebuild is $450.00, while the average cost of a new turbocharger is $1,250.00. The savings alone are usually worth the extra few days it will take to rebuild your turbo over the time it would take to obtain a new one.

What Does A Turbocharger Rebuild Consist Of?

- Besides the obvious fact that the turbocharger must be taken apart, inspected and re-assembled with new bearings, seals and gaskets, there are a few important things that must happen for a thorough turbo rebuild.

- All of the clearances must be measured. This includes the bearing and seal journals, compressor and turbine wheel dimensions, housing bores and of course all of the bearings, collars and seal rings. Turbo Repair keeps a full blue print record of every turbocharger serviced, with all specifications meeting or exceeding the OEM’s original requirement.

- The balance must be checked and corrected. A turbocharger spins at extremely high RPM, so the balancing procedure must be fully performed to correct imbalance issues that arrive from the installation of the new thrust collar assembly. Turbo Repair balancing equipment is calibrated every time a turbo is balanced, and we perform this to a tolerance that exceeds the OEM specification.

- All the parts must be clean, really clean. The turbocharger is a precision device, at this level of detail everything counts. One little piece of stray dirt or carbon can cause severe damage to happen quickly once the engine has been started, greatly reducing the service life of your newly rebuilt turbocharger. Turbo Repair has a dedicated clean room just for turbocharger assembly, ensuring everything remains spotless.

- All the details must be addressed, items such as bolt holes, threads, fittings, gasket surfaces all must be inspected and in proper order. Turbo Repair takes the time to clean every threaded hole, replace any damaged hardware, seal all fittings and make sure the turbocharger you receive is ready to install trouble free.

- Before the turbocharger can be boxed up and shipped, it must include all the of the parts it originally arrived with. Turbo Repair keeps and exact inventory of your turbocharger’s parts, making sure every nut, bolt and fitting is re installed and ready for installation. If any of your parts are not in useable condition, and they are not available from us then you will be notified before your turbocharger is ready for return shipment, giving you the time needed to source a replacement. We will be happy to assist you in any way possible, helping you get your vehicle back on the road promptly.